LED Pin fin heatsink performance optimization

In recent years, the function of cutting-edge FPGA has developed rapidly to an unprecedented height. Unfortunately, the rapid development of functions has also increased the demand for heat dissipation. Therefore, designers need more efficient heat sinks to provide sufficient cooling demand for integrated circuits.

In order to meet the above requirements, thermal management suppliers have launched a variety of high-performance heat sink design that can provide stronger cooling effect under a given capacity. Horn shaped pin fin radiator is one of the more important technologies introduced in recent years. This radiator was originally designed for FPGA cooling, and some of its characteristics make it especially suitable for ordinary FPGA environment.

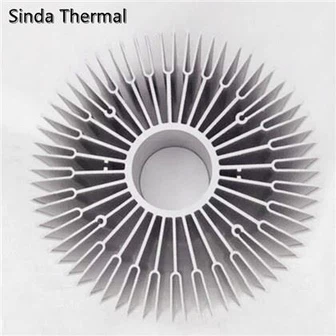

The horn shaped pin fin heat sink is provided with a series of cylindrical pins. As shown in picture below, these pins are arranged outward as fins of heat sink. Due to its unique physical structure, the horn shaped pin fin heat sink is optimized according to the medium and low speed air flow environment, which can achieve unprecedented cooling effect in this environment.

The low thermal resistance of pin fin heat sink mainly benefits from the following characteristics: cylindrical pin, omnidirectional structure of pin array and its large surface area, as well as the high thermal conductivity of base and pin, which help to improve the performance of heat sink. Compared with square or rectangular fins, the resistance of cylindrical pins to air flow is low, and the omni-directional structure of pin array helps the surrounding air flow in and out of pin array conveniently.

In order to achieve significant cooling effect, the heat sink must have sufficient surface area. Otherwise, if the surface area is too small, the heat sink cannot emit enough heat. However, this will hinder the air flow and reduce the thermal performance. This is the inherent contradiction that thermal engineers must face when designing vertical pin heat sink.

By bending the pin outward, the horn pin effectively overcomes the contradiction between surface area and pin density. This method greatly increases the spacing between pins under a given area. Therefore, the surrounding air flow can more easily enter and exit the pin array. The surface of the heat sink is exposed to the air with faster flow rate, and the heat dissipation is greatly increased. This improvement is particularly evident when the air flow speed is low, because the slower the air flow speed, the more difficult it is for the surrounding air to enter the heat sink pin array. Therefore, the horn pin heat sink is most suitable in the environment of low air flow velocity.