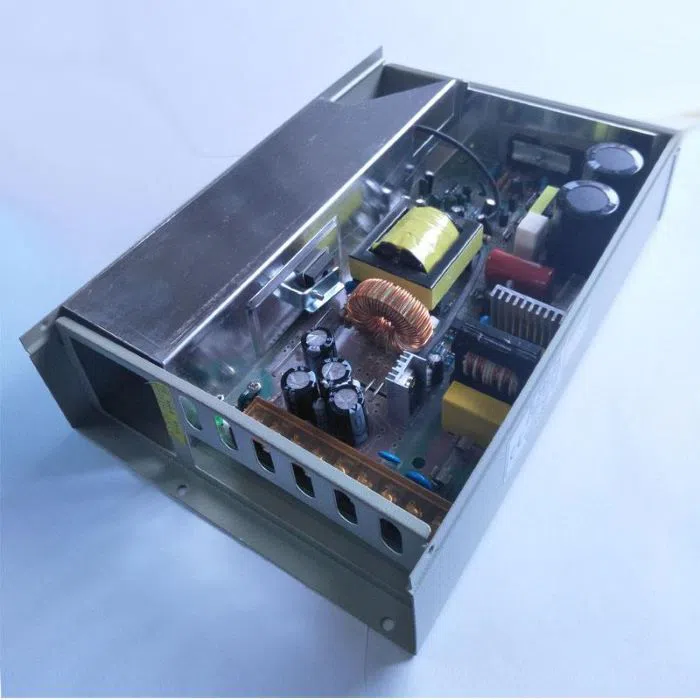

Power Supply module cooling solution

MOS tubes, diodes, transformers and other spare parts in the power module will generate large heat during operation, and the continuous high temperature will have a great impact on its reliability, such as reducing the service life of its internal electrolytic capacitor, reducing the insulation of transformer enamelled wire, transistor damage, material thermal aging, solder joint falling off and so on. Statistics show that the reliability of electronic components decreases by 10% every 2 ℃ rise in temperature. Thermal design is essential to avoid overheating of power modules.

For the thermal design of power module, the thermal design engineer can start with reducing loss and thermal management.

Reduce the energy loss:

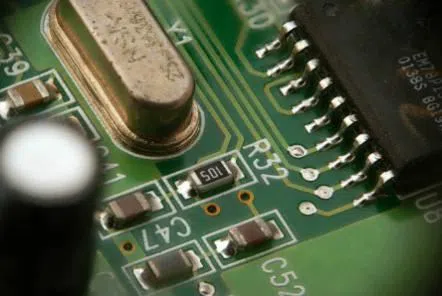

The key components causing loss in the power module mainly include MOS tube, diode, transformer, power inductor, current limiting resistor, etc. Loss is the direct cause of heat generation, and reducing loss is the fundamental to reduce heat generation. How to reduce the loss? Engineers can adopt advanced circuit topology and conversion technology in the process of circuit design to achieve the goal of high power and low loss.

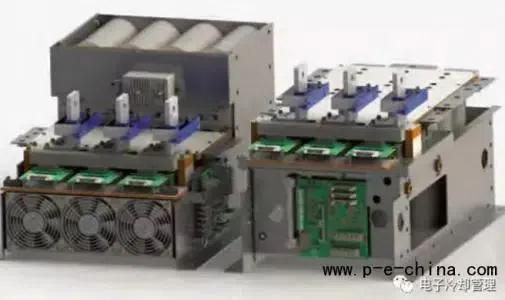

Thermal management:

Thermal management is very important in the design of power module. Because the heating device and the power supply shell are not 100% bonded, there is a small amount of air gap, and the thermal conductivity of the air is very small, only 0.02w/m · K, so the heat on the heating device can not be quickly transferred to the power supply shell, resulting in slow heat dissipation efficiency of the power module.

We can add high thermal conductivity interface materials to fill the gap, eliminate the air between the heater and the power supply, increase the heat transfer area, reduce the thermal resistance and improve the heat transfer efficiency. In addition, the thermal conductivity of thermal conductive silicon film is as high as 1.0 w / m · K, or even higher, more than 50 times that of air, which greatly improves the heat dissipation of power module.

Heatsink and cooling fan is also one of the very effective solutions. For some super high-power equipment, liquid cooling solution can even be considered. Although the cost increases, it's cooling effect is better, which is helpful to improving the service life of power module.