Why do CPUs increasingly use silicone grease instead of solder for heat dissipation?

Intel is increasingly using silicone grease to dissipate heat after IvyBridge, and even the expensive X series is not immune. While it is convenient for overclocking enthusiasts to open the cover, ordinary consumers have doubts. In order to save a few dollars, the high-end series of thousands of dollars sacrifices heat dissipation. Is this really appropriate? What are the reasons for the increasing popularity of silicone grease?

First of all, the thermal diffusion performance of silicone grease is indeed inferior to solder, which is beyond doubt. But CPU silicone grease is not cheap ordinary silicone grease, nor is it the Toothpaste that many people ridicule. The use of silicone grease is indeed to save costs. When the focus is not on the heat dissipation material itself, there are deeper reasons. In order to understand the principles behind it more clearly, let's understand some basic knowledge of CPU.

Die is fixed on the substrate by a group of black filler Underfill, and then coated with silicone grease and then on the heat sink. As Die generates more and more heat, and many people crush Die in order to make the heat sink fit Die closer, Intel began to add protective covers and Die to form the desktop we see now. The basic appearance of the machine CPU:

IHS: Integrated Heat Spreader. It is what we see with the silver lid. Some people think it is made of aluminum, but in fact its main material is copper, because copper has high thermal conductivity. It is silver because it is coated with a layer of nickel. Using nickel as the surface can be more compatible with the silicone grease above:

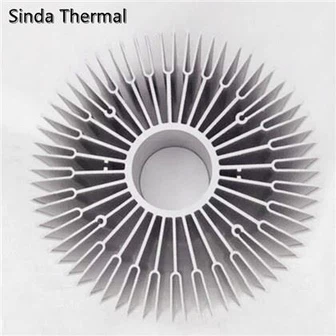

The thermal interface material on the copper cover is called TIM1 (Thermal Interface Material), and the thermal conductivity under the copper cover was once called TIM2. The copper cover can bring the heat of Die to a larger area, and bring the heat to a larger heat sink system (Heat Sink) through TIM1 to facilitate heat dissipation.

What's worse is that the bubbles left in the soldering that are invisible to the naked eye will greatly aggravate this deformation. With the use of the CPU, the cracks that may appear in the solder will also aggravate this effect. Just like the train track will leave expansion joints, the silicone grease TIM2 connection can leave a buffer space for the Die and the copper cover with different expansion ratios, thereby eliminating this danger. A larger Die can better spread the heat to the substrate and IHS, and the deformation per unit area is also small. The small Die will exacerbate this phenomenon and make it more prone to problems.

The solder connection is very difficult, and how to solder the silicon material to the copper cover is a big problem. The material has to be processed many times to ensure effective fit:

Even so, solder will have a negative impact on yield and production costs. Coupled with the increased difficulty of the soldering process caused by the increase in heat density, chip manufacturers are not waiting to find alternatives. So we see that since IvyBridge, the Die becomes very small, the silicone grease TIM2 has been on the table and used more and more. Using silicone grease to make TIM2 has no effect on general users. All CPUs work very well within the TDP, which is guaranteed by the packaging and testing. At the same time, it reduces costs and risks, so why not do it?

For overclockers, the silicone grease TIM2 makes it easy to open the lid. You can try various TIM2 materials on your own, combined with a strong heat dissipation system, which can challenge higher frequencies, which is also a good thing. However, general users should be reminded that there is no warranty after opening the cover, and high temperature affects the life, so they should be cautious.