Working Principle Of Vapor Chamber

Vapor chamber is usually flat in appearance, with a closed cavity inside and working medium inside. According to different usage, there can be capillary structure or no capillary structure inside. Depending on the environment in which the vapor chamber is used, the internal working medium will be different. The soaking plate diffuses heat along the two-dimensional plane, which has better expansion and heat dissipation capacity than the heat conduction tube that diffuses heat along the one-dimensional direction, can make the temperature distribution more uniform, and can carry greater thermal power.

The main function of vapor chamber is to conduct heat, so that the heat diffuses rapidly and tends to be uniform in the device, which is called soaking plate. When the device transfers a large amount of heat, the temperature difference is also very small, which is almost isothermal, so it is called the temperature equalizing plate.The vapor chamber diffuses heat along the two-dimensional plane, which has better expansion and heat dissipation capacity than the heat conduction tube that diffuses heat along the one-dimensional direction, can make the temperature distribution more uniform, and can carry greater thermal power.

In terms of materials, the commonly used vapor chamber are: Copper vapor chamber, titanium vapor chamber, aluminum vapor chamber, stainless steel vapor chamber, etc

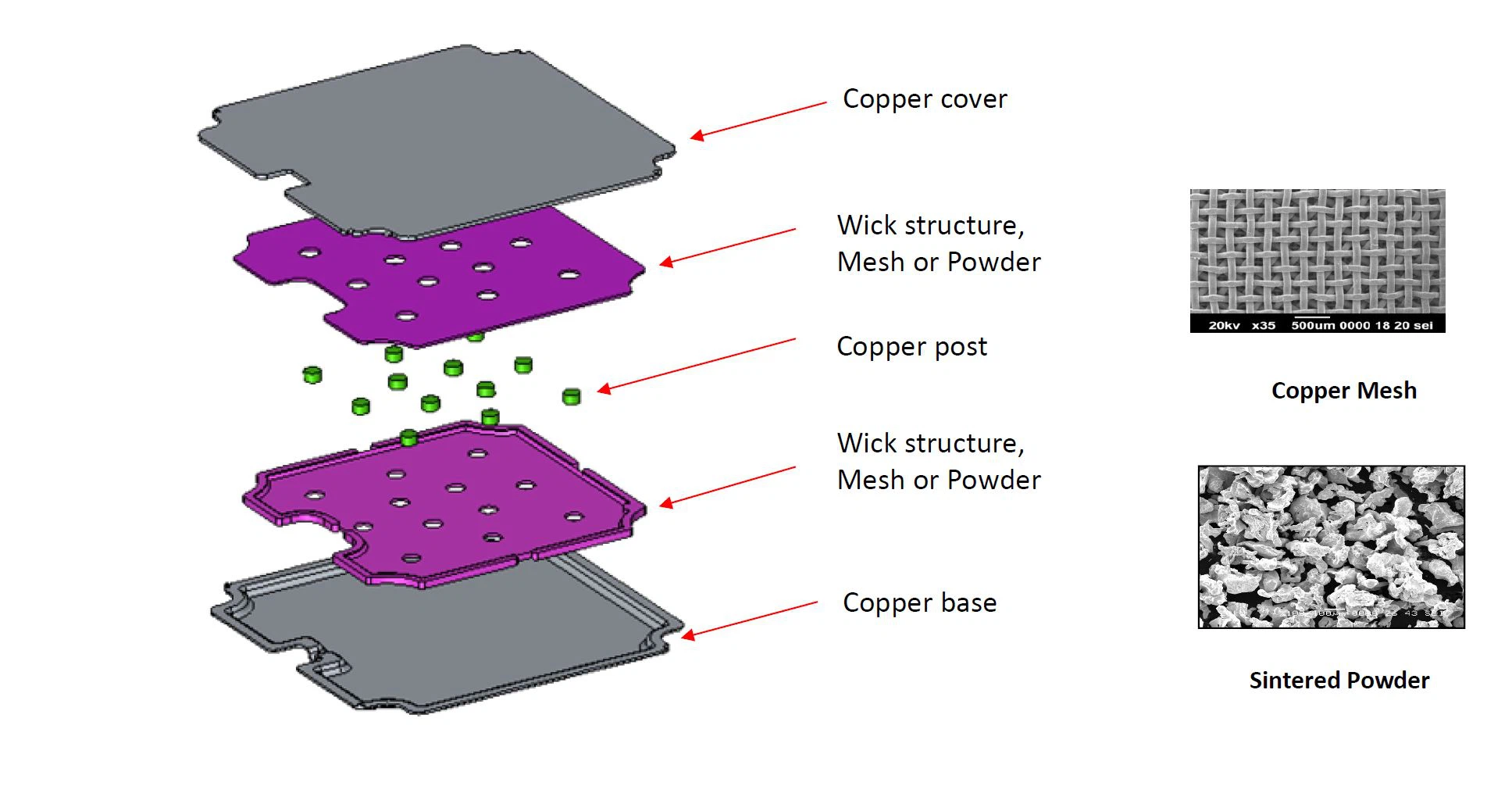

In Structurally, it can be divided into: capillary structure and without capillary structure. Thevapor chamber with capillary structure can be divided into sintered capillary vapor chamber, grooved vapor chamber, woven mesh vapor chamber, fiber vapor chamber and so on. Non capillary structure vapor chamber can be divided into gravity assisted vapor chamber, oscillating vapor chamber and so on.

The working principle of vapor chamber with different structures is also different. For the most commonly used vapor chamber with capillary structure, the capillary structure is usually arranged on the inner surface of the cavity. The working liquid filled into the chamber is locked in the capillary structure under the action of capillary force. A cavity without capillary structure is called a steam cavity. When the heat is transmitted from the shell to the internal capillary structure of the evaporation zone, the working liquid in the capillary structure begins to vaporize after being heated in a low vacuum environment, absorbs heat energy and expands rapidly. The working medium of vapor phase quickly fills the whole cavity. When the working medium of vapor phase contacts a relatively cold area, it will re condense into liquid and release the heat absorbed during evaporation. The condensed working liquid will return to the evaporation place through the pipe formed by the capillary structure and absorb heat again for evaporation.

Vapor Chamber with different structures and processes have different applications:

1. Copper vapor chamber with better thermal conductivity are usually used for electronic chips.

2. The aviation industry usually selects lighter aluminum or titanium vapor chamber because of the weight requirements.

3. Considering the cost, high-power IGBT usually selects aluminum vapor chamber heatsink or aluminum heatsink with small copper chamber.

4. LED lighting use aluminum vapor chamber or soaking column for cost consideration.

5. For lower temperature applications, aluminum or stainless steel vapor chamber is usually selected for thermal conduction or strength.

6. For higher temperature applications, copper or stainless steel vapor chamber is usually selected for thermal conduction or streng.