How to improve the thermal performance of the GPU heatsink

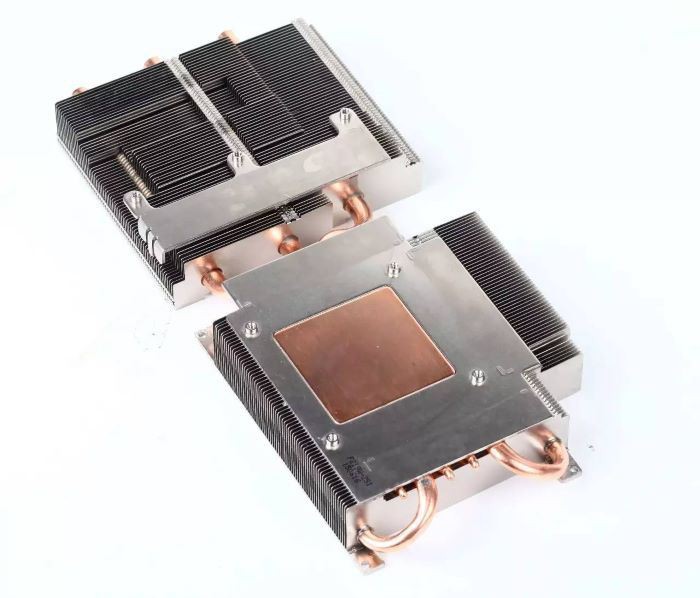

At present, while the performance of the graphics card has increased significantly, the problem of power consumption and heat generation has become increasingly prominent. Among the PC host, the graphics card has become the hardware with the largest heat generation, and the heatsink of the graphics card is becoming larger and larger. At present, more than 90% of radiators use heat pipe and fin welded structural radiators.

Heatpipe design:

In addition to the necessary heat pipe bending, most heat pipes should designed as straight as possible, and the bending degree is relatively small. The straight through heat pipe design is much better in heat dissipation performance. Too many bends increase the thermal resistance and reduce the heat dissipation efficiency. In addition, according to the performance requirements of heatsink module, it is also important to properly select different heat pipe diameter, length, flattening thickness and internal structure of heat pipe.

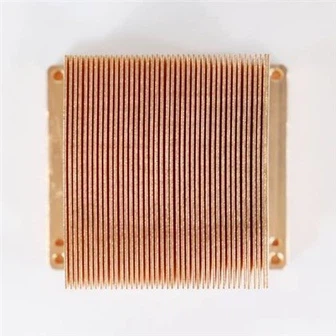

Copper material helps absorb heat faster:

The specific heat capacity of copper is higher than that of aluminum, stainless steel and other materials. Therefore, the heat absorption capacity of copper is better than that of other commonly used metal materials. Proper addition of copper material in the design of graphics card heatsink will help the overall performance. The pure copper base is in close contact with the graphics card core to absorb the heat emitted by the graphics card core. The heat is transferred to the aluminum base plate, fins and heat pipes, and the heat dissipation is accelerated with the help of forced convection air cooling.

Fin stack and soldering process:

In addition to the quality and arrangement of heat pipes, another important factor in the good thermal performance is the utilization rate of fins. For the radiator, it is one thing to guide the heat from the GPU core. How to efficiently guide the heat from the condensing end of the heat pipe to the fins is a very important link. If the heat conduction is not done well, then the heat pipe efficiency is useless.

Usually, reflow soldering technology will be used to directly weld the heat pipe and fins, which will make the heat pipe and fins fit more closely and improve the heat conduction efficiency. The process design requirements of "zipper fin" are very high. If the manufacturing process level is not good, casing uneven fin density, or individual fins do not fit closely with the heat pipe, the overall heat dissipation performance of heatsink module will be greatly affected.