Copper Chipset Heat Sink

When talking about heat dissipation, thermal conductivity is a fundamental characteristic of a heat sink material to understand. Thermal conductivity relates to the materials ability to transfer heat away from the center or source of heat. It measures the ability of a material to move heat away from a point of application. It is measured as “watts of energy per meter of material per degree Kelvin” (W/m K). The higher this number is, the greater the thermal conductivity of the material. Copper has a high thermal conductivity at 401 W/m K compared to aluminum at 237 W/m K.

Product Introduction

When it comes to the performance of our electronic devices, the role of the chipset cannot be underestimated. Chipsets are also known as microchips or simply chips, act as the brains of our devices, allowing them to function effectively and efficiently. It is responsible for performing various operations and coordinating between different components. However, since these chips tend to operate at high speeds, they generate a lot of heat, which can cause performance issues or even damage the chip if not managed properly. This is where copper chipset heatsinks come into play.

Copper chipset heatsink is a critical component in modern electronic equipment, helping to efficiently dissipate the heat generated by chipsets. It acts as a cooling mechanism, absorbing heat and moving it away from the chip, preventing overheating and maintaining peak performance. Copper has excellent thermal conductivity and is one of the best materials for efficient heat transfer, this feature allows the copper heat sink to quickly absorb the heat generated by the chipset and dissipate it into the surrounding environment. In addition, copper has impressive corrosion resistance, ensuring the longevity and reliability of the heatsink. The design of the copper chipset heat sink is equally important. Its structure includes fins or ridges that increase the surface area of the heat sink, this enlarged surface area facilitates better heat dissipation because it allows more air to come into contact with the heatsink. Also some radiators also feature heat pipes to further increase cooling efficiency, these heat pipes use a combination of evaporation and condensation to move heat away from the chip more efficiently.

One of the main advantages of a copper chipset heatsink is its ability to prevent overheating. When a chipset handles a lot of calculations and multitasks, it naturally generates heat, if the heat could not be dissipated in time, this heat can cause performance degradation and eventually permanent damage to the chip. However, a copper heat sink helps keep temperatures within safe limits, ensuring consistent performance and reliability, this is especially beneficial for high-performance devices that require a lot of processing power, such as gaming computers, servers, and graphics processing units (GPUs). Another noteworthy benefit of a copper chipset heatsink is its contribution to energy efficiency. When the chip works at high temperature, it consumes more power to work properly, by effectively dissipating heat, the copper heat sink helps to reduce the temperature, thereby reducing power consumption. This not only increases the energy efficiency of the device, but also extends battery life, resulting in a more sustainable and environmentally friendly solution. Additionally, the use of a copper chipset heatsink enables the device to achieve higher levels of performance. When a chip is running cooler, it can run at its maximum capacity without thermal throttling or the risk of performance degradation due to overheating. This improved thermal management enhances the overall agility and responsiveness of the device, making it valuable for applications that require fast and accurate processing, such as video editing or computer-aided design (CAD) software.

Varieties of heat sink

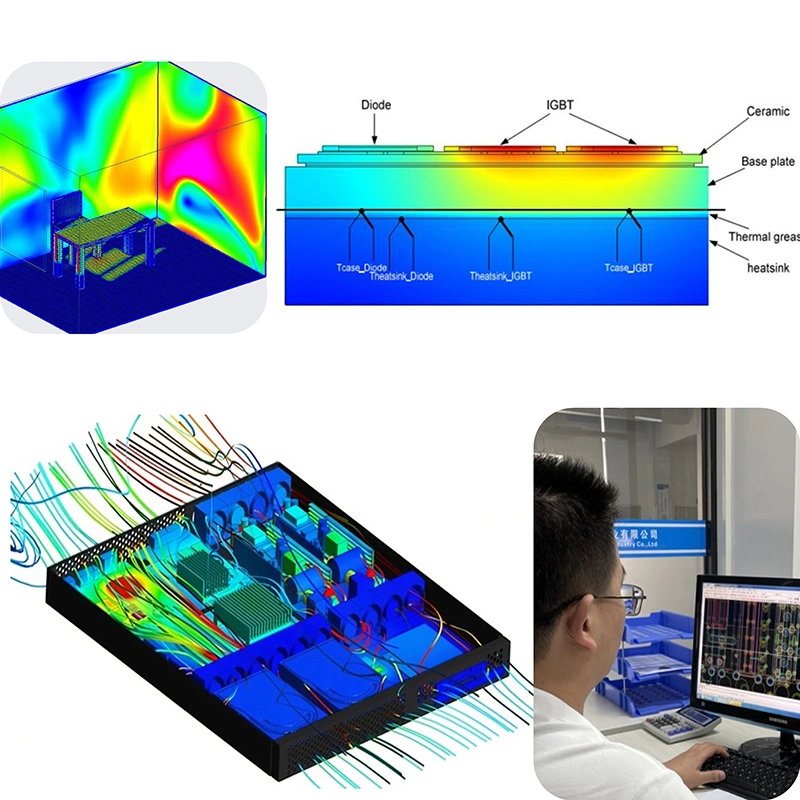

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: copper chipset heat sink, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China

You Might Also Like

Send Inquiry