Heat Pipe PCB Heatsink

As electronic technology continues to advance, electronic devices continue to become more compact and powerful, which increases the power density has created a greater requirements for effective cooling solutions, particularly when it comes to printed circuit boards (PCBs). In recent years, the use of heat pipe heat sinks has become increasingly popular in the PCB industry.

Product Introduction

As electronic technology continues to advance, electronic devices continue to become more compact and powerful, which increases the power density has created a greater requirements for effective cooling solutions, particularly when it comes to printed circuit boards (PCBs). In recent years, the use of heat pipe heat sinks has become increasingly popular in the PCB industry.

Why PCBs need effective cooling solutions? As electronic components operating, they would generate a hugh amount of heat, excessive heat can cause components to fail or degrade prematurely, leading to poor performance or even complete system failure. PCBs are particularly susceptible to overheating due to their compact size and component density, without proper cooling, the heat generated by components can quickly be accumulated, leading to thermal issue.

One common solution for cooling PCBs is to use heat sinks, the tranditional heat sinks are typically made of metal and use fins to dissipate heat, but traditional heat sinks have limitations, they are bulky and require substantial space, moreover, their heat dissipation capabilities can be limited due to factors such as airflow and thermal resistance. So the heat pipe heat sink are designed to solve these problems perfectly. Heat pipe is a passive heat transfer device that utilizes a closed transfer cycle by a liquid coolant absorbs and transfers heat away from the heat-generating element, this coolant then undergoes a phase change, becoming a vapor, and absorbing the heat, the vapor then travels along the heat pipe to an area of lower temperature, which it's called condenser side, where it condenses back into a liquid and releases the heat, this cycle repeats continuously, allowing for efficient heat transfer.

The use of heat pipe heat sinks offers several benefits over traditional heat sinks. Firstly, heat pipe heat sinks are typically much thinner than traditional heat sinks, making them ideal for applications where space is limited. Additionally, heat pipes can transfer heat more efficiently than traditional heat sinks due to their high thermal conductivity, this means that less energy is required to transfer heat away from the component, resulting in lower operating temperatures and increased component lifespan. Another benefit of heat pipe heat sinks is that they are passive devices, meaning they do not require any external energy source to function, which makes them ideal for use in applications where power consumption is a concern, such as in portable devices. Additionally, because heat pipe heat sinks are sealed and contain no moving parts, they are highly reliable and require little maintenance.

Varieties of heat sink

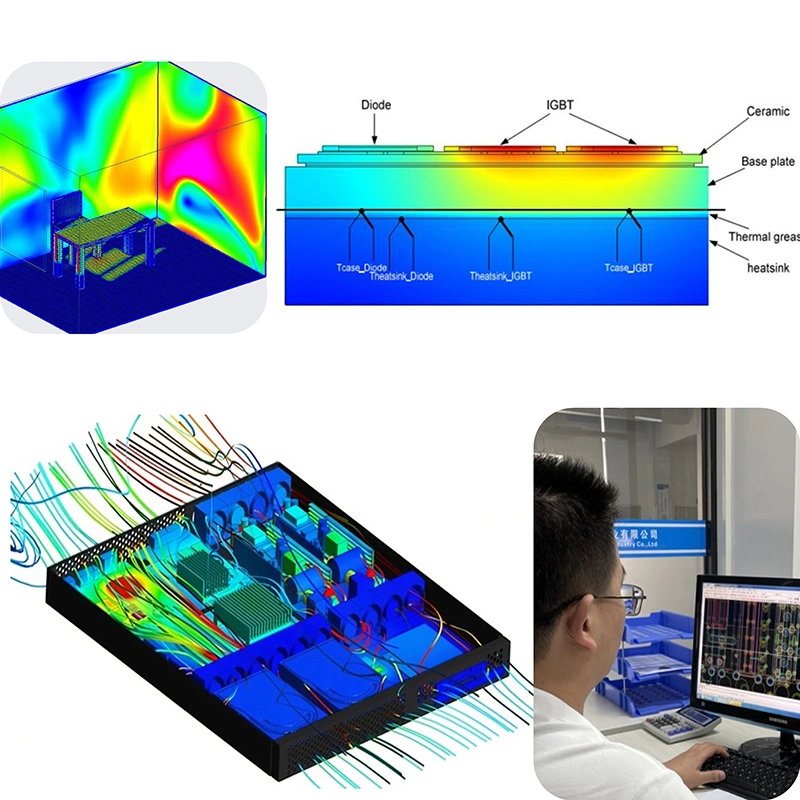

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: heat pipe pcb heatsink, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China

You Might Also Like

Send Inquiry