Aluminum Extruded Pin Fin Heatsink

To manufacture aluminum extruded pin fin heat sinks, firstly we should get the aluminum extrusion profiles by extruding the ingot through the tooling die. We generally need to put the aluminum billets in a high temperature environment of 350~500 °C, use a large extruder to apply high-intensity pressure, and extrude the aluminum billtes through tooling die to make the designed cross-sectional shapes. Definitly the tooling die needs to be designed. Aluminum extrusion production process is aluminum rod, heating, extrusion, cut to length, cross cut. Aluminum extrusion heat sinks are widely used in various fields such as heat exchangers and radiators of refrigeration and heating equipment, air conditioners for vehicles and other daily necessities, from leisure products to aviation equipment and other fields, so the development of aluminum extrusion heat sink is very active.

Product Introduction

Having an effective cooling system is essential when managing heat in electronic equipment. Aluminum extruded pin fin heat sink is one of the most effective thermal solutions in the electronic devices.

Aluminum extruded pin fin heatsinks are very efficient at cooling electronics due to their structure design. The heat sink consists of a series of pins extending outward from the substrate. These pins increase the surface area of the heat sink, allowing for greater heat transfer. Airflow is directed through the small gaps between the pins, which increases the cooling capacity of the heatsink.

Aluminum is a lightweight and durable metal capable of withstanding various temperatures and weather conditions. This makes heat sinks perfect for using in a variety of applications ranging from consumer electronics to industrial machinery.

Aluminum is a great thermal conductor, most importantly, it also has excellent heat dissipation ability even better than copper, the characteristic of aluminum makes aluminum extruded pin fin heat sink be a great thermal solution.

Using aluminum extruded pin fin heatsinks is their cost effectiveness, compared with copper, aluminum is a very cost-efficient metal, and the manufacturing process for such heat sinks is relatively simple and inexpensive, which means that the end product is affordable. This cost-effectiveness makes heat sinks a popular choice for a wide range of electronic applications.

Another important factor to consider when choosing a radiator is ease of installation. Aluminum extruded pin-fin heatsinks are easy to install , the heat sink can be attached directly to the device using thermal paste, tape, or screws.

Product specifications

| Material | Aluminum alloy | Certificates | ISO 9001:2015,ISO 14001:2015 |

| Product dimension | Customized | Type | Extruded heat sink |

| Process | Extruding, CNC, drilling | Lead time | 2-3 weeks |

| Surface finish | Anodizing | Packing | Tray, carton |

| OEM/ODM | Yes | Quality control | 100% |

| Application | CPU, inverter,IGBT,LED,BGA,etc. | Warrantly | 1 year |

Varieties of heat sink

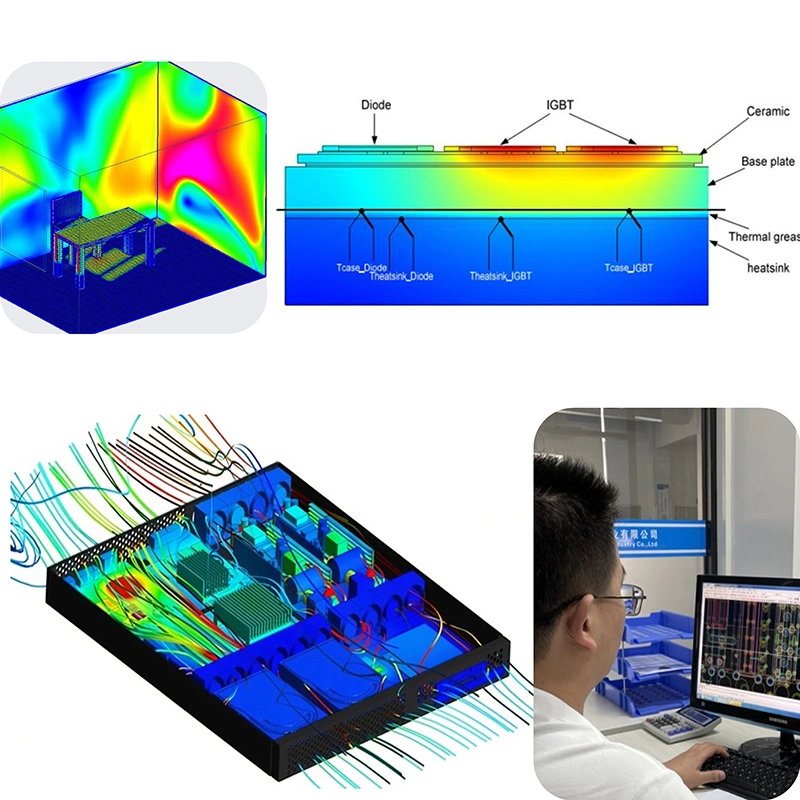

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is devoted to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

Q: what's the lead time for this kind of heat sink

A: it based on the volume, the lead time of prototype samples is 1-2 weeks, for mass production, the lead time is 3-4 weeks.

Q: Is there any MOQ limit?

A: No, we don't set up MOQ, 1pcs is available.

Q: are you a trade company or you own your plant?

A: we have a factory, so the cost is based on factory calculation, which can be much more competitive.

Q: what's the scale of your factory?

A: Our Factory owns about 30 CNC machines and over 30 stamping machines, over 100 empolyees.

Hot Tags: aluminum extruded pin fin heatsink, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China, Extruded Aluminum Heat Sinks, Extruded Heat Sink, Heatsink Extruded Aluminium Profile, Extruded Aluminum Sink, Extruded Heat Sink Enclosure, Extruded Aluminum Heatsink Stock

You Might Also Like

Send Inquiry