Aluminum Transistor Heat Sink Extrusion

A transistor is an electronic device that plays a crucial role in many electrical circuits. However, like any other electronic component, it generates heat while operating, the heat produced by the transistor can lead to a rise in temperature, which can negatively impact the performance of the transistor and in worst-case scenarios, cause component failure, so thermal management for the transistor is very important.

Product Introduction

A transistor is an electronic device that plays a crucial role in many electrical circuits. However, like any other electronic component, it generates heat while operating, the heat produced by the transistor can lead to a rise in temperature, which can negatively impact the performance of the transistor and in worst-case scenarios, cause component failure, so thermal management for the transistor is very important.

The Need of a Heat Sink for Transistors

A heat sink is a device to dissipate heat which is generated by the transistor when it is in operation. Without a heat sink, the heat produced by the transistor remains trapped in the device, which can lead to thermal problems, which often results in the device operating at a lower efficiency, or at worst, failure of the component, which can have serious consequences. The transistor is a semiconductor device and, like any semiconductor device, it has a trend of generating heat when it is in operation due to the current flowing through it, which in turn generates heat due to the resistance that exists. Overheating is bad for electronic components since it can cause them to malfunction or fail, a high temperature leads to more resistance within the transistor, which in turn causes it to draw more power to compensate, which can ultimately lead to the transistor’s failure. So it is crucial to remove the heat as fast as possible so that the temperature remains in a range that is safe for the transistor to operate.

Choosing an Aluminum Heat Sink Extrusion

A heat sink helps to remove the heat produced by the transistor, preventing it from accumulating and causing damage to the device. Heat sinks come in different materials; the most commonly materials are aluminum and copper due to they have excellent thermal conductivity, but aluminum heat sink extrusion remains the best option for many reasons.

First, aluminum has excellent thermal conductivity, which makes it a perfect material for heat sinks, it easily transfers heat from the transistor to the surroundings, which helps to protect the internal components of the device from overheating. Secondly, aluminum is a lightweight material, which makes it easy to handle and install. A light heat sink is portable and can easily be fixed to the device's surface, this makes aluminum heat sinks the ideal choice for portable electronic devices such as laptops.Thirdly, aluminum is an affordable material, which makes it a cost-effective option for heat sink manufacturing. The cost of aluminum extraction and processing is generally lower compared to other metals like copper. Another advantage of an aluminum heat sink extrusion is that it can be fabricated easily, extrusion is a process by forcing aluminum billet through a designed die. This process can be used to produce heat sink designs that match the shape of the transistor. It allows for the creation of more complex heat sink designs that can be custom made to fit specific transistors. So heat sink manufacturers can easily design and produce aluminum heat sinks of different shapes and sizes to match specific transistors.

Varieties of heat sink

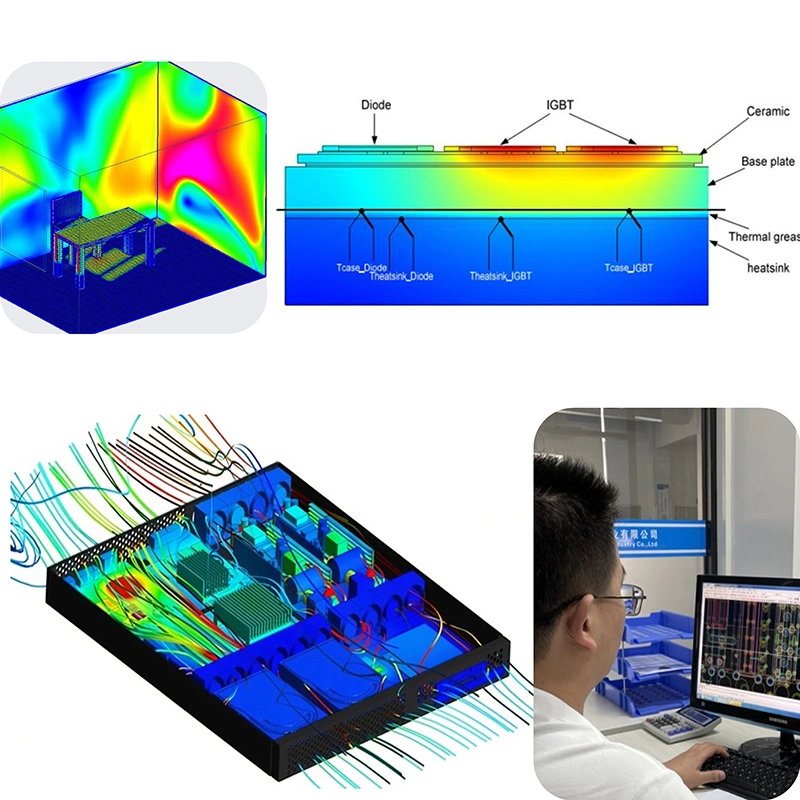

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: aluminum transistor heat sink extrusion, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China, Extruded Heat Sink, Extruded Heat Sink Enclosure, Extruded Aluminum LED Heatsink, Heatsink Extruded Aluminium Profile, Anodized Extruded Sink, Extruded Heat Sink Profiles

You Might Also Like

Send Inquiry