Application of thermal design in surveillance camera

All electronic and electrical equipment have a common problem: as long as it works, it will heat up. Security equipment basically works 24 hours a day. If the heat dissipation design of security products is defective, heating will not only accelerate the aging of security electronic components, but also cause irreversible damage to them.

Since the surveillance camera is equipped with an infrared lamp with high calorific value, after the infrared lamp is started, there will be a large amount of heat concentration in the front of the infrared camera. If the heat dissipation is not uniform, the normal operation of the camera will be affected. For example, if 50 ¢ 5 infrared light boards operate for a long time, the temperature on the LED board can almost reach about 90 degrees, and the CCD image sensor behind the LED board becomes the most direct victim. The CCD image sensor can directly convert the optical signal into analog current signal. After amplification and analog-to-digital conversion, the current signal is used to realize image acquisition, storage Important components for transmission, processing and reproduction.

There are six common heat dissipation methods for surveillance cameras:

1. Reduce the current. Using the infrared lamp with low power consumption instead of the infrared lamp with high power consumption can reduce the calorific value, but the effect is certainly not obvious when irradiating for a long distance.

2. Add a cooling fan inside. The service life of a surveillance camera with a cooling fan is significantly longer than that of a camera without a cooling fan. The long-life (70000 hours) ball cooling fan, coupled with the temperature control function (adjusting the speed through temperature sensing), can better escort the security surveillance camera.

3. Use a constant current power supply. Keep the current constant and control the heat dissipation of LED .

4. Grouping arrangement of LED lights. For example, 24 infrared rays can be arranged into three groups to reduce heat .

5. Selection of structural materials. For example, the LED lamp board and shell are made of aluminum alloy and other materials with good heat dissipation.

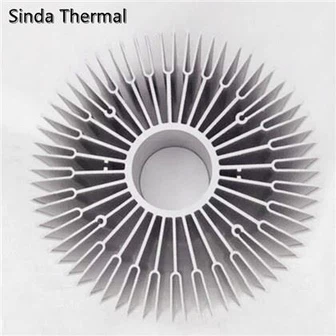

6. Heat conducting material and heat sink application. The heat of the heating body is transmitted to the shell by using heat conducting medium materials and heat radiating fins, and then the heat is dissipated by natural convection.

Thermal design plays a key role in all walks of life, especially in the field of security monitoring, when the equipment needs to be operated continuously for a long time, a good thermal design scheme will make the relevant products have a longer service life and better service experience. Sinda Thermal can provide varieties heatsinks and coolers which inlcuding aluminum extruded heatsink, high performance heatsink, copper heatsink, skived fin heatsink, and heat pipe heatsink widely used in many application fields. please contact us if you have any questions about thermal solution.

website: www.sindathermal.com

contact:castio_ou@sindathermal.com

Wechat: +8618813908426