Mainly server cooling technology

Server cooling technology mainly includes: air cooling, liquid cooling, heat transfer and intelligent control. Among them, air-cooled heat dissipation and liquid-cooled heat dissipation are still the two core technologies in the field of server heat dissipation technology. In addition, one of the biggest technical features in the field of server heat dissipation is that a single heat dissipation technology is rarely used.

(1) Air-cooled heat dissipation

The principle of air-cooling heat dissipation is simply to guide the wind, blowing cold air into the heating element, or drawing out the hot air from the heating element. Common technologies include fans and air hoods. The former can use an exhaust fan or a blower fan, and the latter can guide the wind according to a specific air duct to form a specific airflow direction during the heat dissipation process.

The representative methods are:

1. Install a large number of cooling devices on the server motherboard, and use the cooling device to export the heat generated by the electronic components on the motherboard. Then install a large number of fans above and below the server cabinet, and the heat is taken away by the airflow generated by the fans. Achieve heat dissipation effect.

2. Place the air baffle on the electronic components of the server motherboard. Its front end is connected to the fan group to form an air inlet. The rear end is set at the back of the motherboard and the outlet pipe diameter is reduced to form a convection zone. At the same time, there are divided parts to divide the convection zone. , The area formed by the blocking component, the sealing component and the dividing component is the corresponding air duct, and the electronic components that generate heat are located in the air duct, and the heat generated by it is taken away by the airflow in the air duct, so as to achieve the heat dissipation effect.

(2) Liquid cooling

The principle of liquid cooling heat dissipation is simply to use heat convection or heat conduction to take away the heat of the heating element through the immersion or flow of liquid. Common liquid cooling methods are: immersion and liquid cooling circuit. Since electronic components are easily damaged when exposed to water, the liquid used for immersion is oil, fluoride and other non-conductive liquids, while the liquid cooling circuit contacts the electronic components with a closed liquid circuit, and the electronic components are produced by the flow of liquid The heat is taken away, and the liquid is often cold water.

The specific representation methods are:

1. The server is set up as a closed container, which contains a large amount of liquid coolant, such as fluorinated hydrocarbons, which can flood all the chips in the server. There is a part of air space above the liquid coolant, which can be used when the temperature of the server rises. The gas is compressed into liquid. The chip is immersed in the liquid coolant. The liquid coolant takes away the heat of the chip by evaporation and condensation. The steam rises from the coolant and then condenses into droplets and flows into the coolant. In the container, liquid cooling liquid and steam can circulate in a certain route. The cooling liquid evaporates and takes away heat. After cooling by the radiating plate, it becomes liquid and then merges into the coolant.

2. The heating elements in the server form a single unit, and the heat generated by it is dissipated through the water-cooled sleeve. The cooling liquid flows in the direction indicating the liquid circulation. The cooling liquid is driven by the micro pump. The heat is released and returned to the micro pump. The fixed piping, the first heat receiving part, the second heat receiving part and the large pump are installed in the server cabinet, and the on-off valve provided in the fixed piping of the cabinet is opened. Each monomer circulates, the water-cooled sleeves, heat exchangers in each monomer are in thermal contact with the first and second heated parts in the casing, and the heat generated by the heating elements of each monomer is transferred to the casing, and then through The whole case dissipates heat naturally or the cooling fan arranged in the case is forcibly released into the air.

(3) Heat transfer

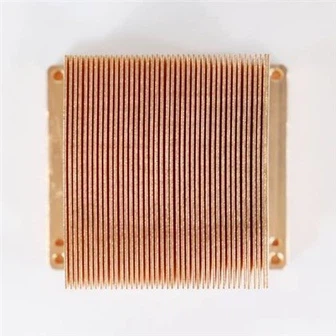

The principle of heat transfer is to use heat conduction to dissipate heat, that is, to transfer heat from a high-temperature object to a low-temperature object. Common heat dissipation technologies are: heat sink, cooling plate and semiconductor board. The heat dissipation technology using semiconductor boards is based on the Peltier principle, that is, when a circuit composed of two different conductors A and B is connected to a direct current, one connector releases heat, the other connector absorbs heat, and when the current direction is changed, it absorbs heat. The heat and exothermic parts are interchanged, so as to achieve the heat dissipation effect.

(4) Intelligent control

The principle of intelligent control is to use sensors to monitor the temperature and load inside the server, and adjust the fan speed or liquid flow rate through the corresponding control circuit, which is a kind of intelligent heat dissipation.

The specific representation is as follows:

The power supply provides power to the CPU and the cooling fan. When the cooling fan is working, it guides the airflow through the CPU and other components. The controller controls the operation of the cooling fan according to the information sent by the power supply unit and temperature sensor. There is also a cooling fan on the power supply unit. The load sensor monitors or detects the parameter indicating the load of the power supply unit. The controller activates the voltage applied to the cooling fan from the power supply and adjusts it to an appropriate level according to the estimated power load and the monitored temperature.