Production Process of thermal conductive PAD

Thermal conductive PAD is a kind of heat conducting medium, which is used to reduce the contact thermal resistance between the heat source surface and the contact surface of the radiator. It can also be called thermal conductive silicone sheet, thermal conductive silicone pad, soft heat dissipation pad and so on. There are some differences in the production process of thermal conductive PAD from different manufacturers. The production process of thermal conductive PAD mainly includes: raw material preparation → plastic refining and mixing → molding vulcanization → trimming and cutting → inspection, etc.

1. raw material preparation :

The thermal conductivity of ordinary organic silica gel is poor, and the thermal conductivity is usually only about 0.2w/m · K. However, the thermal conductivity can be improved by mixing thermal conductive fillers in ordinary silica gel. Common thermal conductive fillers include metal oxides (such as Al2O3, MgO, BeO, etc.) and metal nitrides (such as sin, AlN, BN, etc.). The thermal conductivity of the filler is not only related to the material itself, but also closely related to the particle size distribution, morphology, interfacial contact and the degree of binding within the molecule. Generally speaking, the heat conduction effect of fibrous or foil heat conduction filler is better.

2. plastic refining and mixing:

Plasticizing and mixing is a process of silica gel processing, which refers to the use of mechanical or chemical methods to reduce the molecular weight and viscosity of raw rubber to improve its plasticity and obtain appropriate fluidity to meet the needs of further processing of mixing and molding. The raw material of thermal conductive pad is generally destroyed by mechanical high-speed stirring. After color matching and mixing, the Milky silica gel is transformed into pieces of various colors.

3. molding vulcanization:

If you want to make a soft, elastic and tensile heat-conducting silica gel gasket, you need to use the organic silica gel that has undergone secondary vulcanization. Vulcanization can actually be called curing. After the liquid thermal conductive silica gel is heated and formed in the first stage, its crosslinking density is not enough. It is necessary to make its further vulcanization reaction to increase the pull-up strength, resilience, hardness, swelling degree, density and thermal stability of thermal conductive silica film, which are greatly improved compared with one-time vulcanization.

4. trimming and cutting:

The thermal conductive silicon film after high temperature treatment needs to be placed for a period of time to be naturally cooled and then cut in different sizes and specifications, rather than other rapid cooling methods. Otherwise, it will directly affect the product performance of thermal conductive pad.

5. inspection:

The main items to be tested for finished products include: thermal conductivity, temperature resistance range, volume resistivity, voltage resistance, flame retardancy, tensile strength, hardness, thickness, etc.

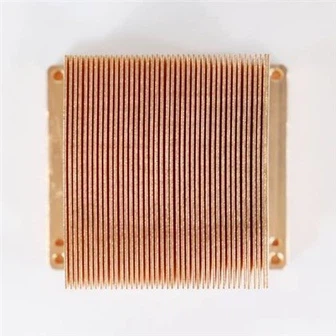

Thermal conductive PAD are widely used in many fields ,such as CPU , GPU, LED, LCD, medical equipment ,laptop,Audio,etc, how to choose a correct thermal conductive PAD for the electric device is important in thermal design. Sinda Thermal has rich experience in helping customer design the most suitable thermal solutions ,Besides, we also provide various heatsinks, such as :extrusion heatsink, skive fin heatsink , stamping fin assembly ,heatpipe soldering modules, vapor chamber heatsink, liquid cooling plate,fan cooler,etc. Please contact with us if you need any help on thermal issues.

website: www.sindathermal.com

contact:castio_ou@sindathermal.com

Wechat: +8618813908426