Battery Liquid Cooling Cold Plate

As the demand for renewable energy continues to grow, so does the need for efficient and reliable energy storage systems. Among the various technologies available, battery solutions have proven their potential to revolutionize the way we store and utilize energy. However, battery performance and safety remain key concerns for researchers and engineers in this field. To address these issues, liquid-cooled cold plates for batteries have designed as a promising solution to improve battery performance while ensuring safety.

Product Introduction

As the demand for renewable energy continues to grow, so does the need for efficient and reliable energy storage systems. Among the various technologies available, battery solutions have proven their potential to revolutionize the way we store and utilize energy. However, battery performance and safety remain key concerns for researchers and engineers in this field. To address these issues, liquid-cooled cold plates for batteries have designed as a promising solution to improve battery performance while ensuring safety.

Battery liquid cooling is a technology that uses a liquid coolant to regulate the temperature of the battery. Air cooling has traditionally been the method of choice for cooling battery systems, but as energy density increases, air cooling alone is not sufficient to dissipate the excess heat generated during charging and discharging operations. This excess heat can degrade battery performance and even lead to safety hazards such as thermal runaway.

To overcome these limitations, battery liquid cooling systems have attracted attention in recent years. These systems typically consist of a cold plate used as a heat exchanger and a liquid coolant such as water or a mixture of water and glycol. When the battery is operating, the liquid coolant absorbs heat from the battery cells and carries it away, effectively cooling the system. The battery liquid cooling cold plate plays a vital role in ensuring efficient and uniform cooling of the battery cells. It is specifically designed to maximize heat transfer and optimize cooling performance. The cold plate consists of a network of copper tube channels that make direct contact with the battery cells, liquid coolant flows through these channels, absorbing heat from the battery and dissipating it into the environment.

One of the main advantages of using a battery liquid cooling cold plate is that it provides more even cooling of all the batteries. In an air-cooled system, airflow distribution can be uneven, causing hot spots and temperature variations between cells, this ultimately leads to reduced performance and a shorter lifespan of the battery pack. With a liquid-cooled cold plate, the coolant draws heat evenly from each battery, preventing temperature imbalances and improving overall system performance. Additionally, a battery liquid-cooled cold plate helps maintain optimal operating temperatures for the battery cells, high temperatures can accelerate battery degradation, reduce capacity and increase the risk of thermal runaway. By actively cooling the battery, the cold plate ensures that the battery operates within a safe temperature range, extending its lifespan and improving reliability.

In addition to cooling capabilities, battery liquid cooling cold plates have other significant advantages. For example, it can serve as a structural component within a battery system, providing mechanical support and improving the overall robustness of the system. The cold plate also acts as a barrier, isolating the battery cells from potential external hazards such as shock or vibration. This extra protection further enhances the safety and durability of the battery system.

Varieties of heat sink

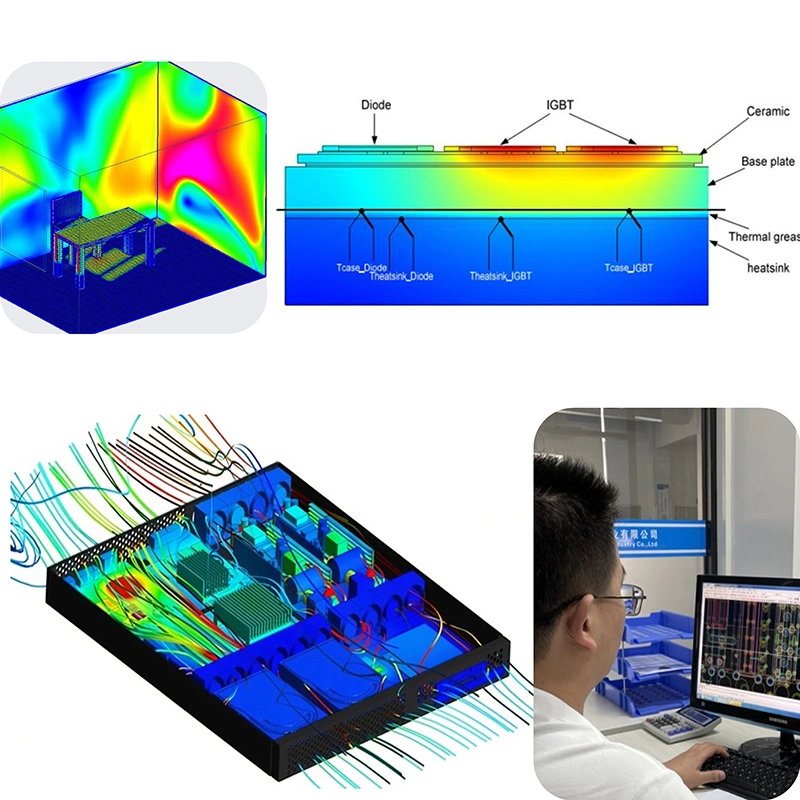

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: battery liquid cooling cold plate, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China, Active Liquild Cooling, Passive Liquild Cooling, Liquild Cold Plate with Copper Tube, Liquid Cooling, Liquild Cooling Plate, Liquid Assist Air Cooling

You Might Also Like

Send Inquiry