Aluminum Skived Passive Heat Sink

The Skived fin passive heat sink is one of the most efficient passive cooling solutions available for electronic devices. Skiving is a process by peeling a thin fin off the base material using a sharp tool, this process builds a skived fin heatsink which has thin, efficient fins that can dissipate heat quickly and effectively.

Product Introduction

The Skived fin passive heat sink is one of the most efficient passive cooling solutions available for electronic devices. Skiving is a process by peeling a thin fin off the base material using a sharp tool, this process builds a skived fin heatsink which has thin, efficient fins that can dissipate heat quickly and effectively.

One of the biggest advantages of skived fin passive heat sinks is their high fin density which creates much more surface area than extrusion process, this allows for more efficient heat transfer and enables the heatsink to handle higher heat loads. Additionally, the skived fins are typically sliced at a very shallow angle, which allows for more fins to be cut into a smaller space. This improves the heat sink's ability to dissipate heat in tight spaces.

Skived fin passive heat sinks are manufactured by using a skiving process to create very thin fins and high fin density which can significantly improve the thermal performance, as the outstanding thermal performance, skived fin passive heat sinks are commonly used in a variety of applications, including high-performance electronics, computer servers, and automotive applications. They are ideal for any application that requires high heat dissipation without the need for additional components, such as fans or liquid cooling systems.

Aslo the skived fin passive heat sink is an excellent solution for those looking for a cost-effective and efficient way to dissipate heat in their electronic devices. With their high surface area and precise, thin fins, skived fin heat sinks are an outstanding thermal management solution that can help extend the lifespan of electronic components and improve their overall performance. Whether you are looking to cool an electronic device or maximize the performance of your computer server, a skived fin passive heatsink is a reliable and effective choice.

Varieties of heat sink

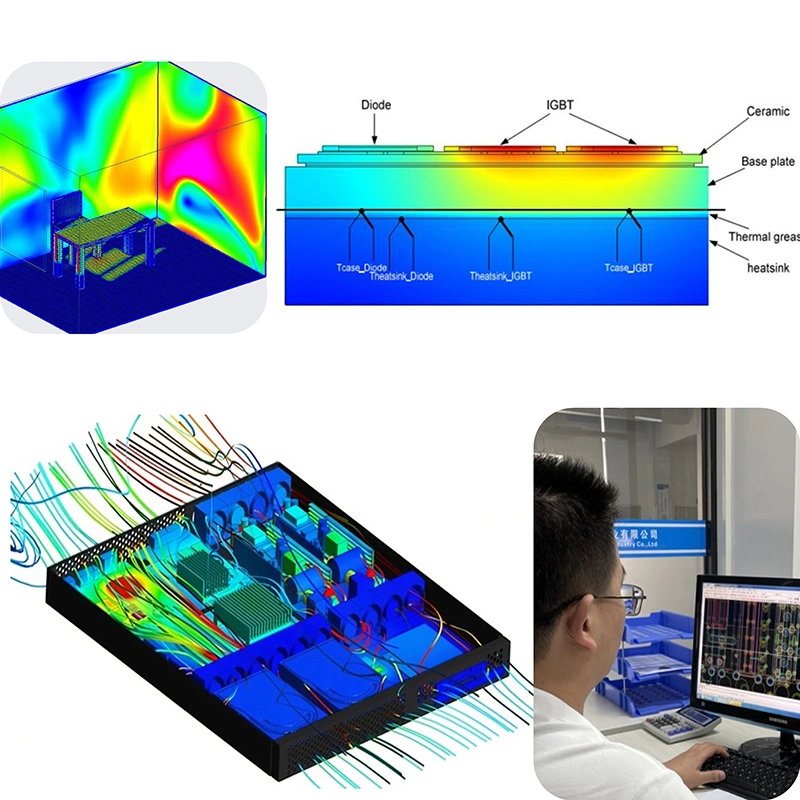

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: aluminum skived passive heat sink, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China, Skived Fin Process, Skived Fin Copper Heat Sink, Skived Fin Heatsink, Aluminium Skiving Fin Heatsink

You Might Also Like

Send Inquiry