carbon steel SA36 SS41 CNC drilling Machining heat exchanger Tube Sheets Baffles Support Plates Tube Plates Tubesheets

From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping. We have a professional team to control the quality. Experienced engineers, precision machines, CMM and closed-loop QC system.

Product Introduction

We are committed to optimizing product structure, reducing production and operation costs of Vapour Chamber Liquild Cooling, CNC Machining, 6 Heat Pipe CPU Cooler so as to create new economic growth points. We sincerely serve every customer and constantly improve the quality of our products. We establish a systematic, scientific, strict and standardized management system and act strictly in accordance with the rules and regulations. We serve both the company and the customers on the basis of the principle of respect for the market and the customers with honesty.

In manufacturing industry, CNC machining is a popular process which is used to build components in a variety of materials. One of the most popular materials is aluminum, which is used in many industries due to its light weight, durability and ease of machining.

CNC machining is a manufacturing process that uses computer software to control and automate the tools and machines to manufacture the features as designed. The process starts with a design, usually created in CAD software, and converts it into machine code that a CNC machine can understand and execute.

The first step in producing high-quality aluminum sheet through CNC machining is selecting the correct grade of aluminum. Aluminum can be made in various grades, each with different properties and uses. For example, if you are producing parts that require high hardness and thermal conductivity, you can choose a high-grade aluminum alloy such as 6061 or 6063.

Once the aluminum is selected, the next step is to prepare the material for machining. Aluminum must be cut to the correct shape and size to fit the CNC machine. This can be done manually with a circular or band saw or with a specialized aluminum cutter.

The next step in the CNC machining process is to secure the aluminum sheet to the table of the CNC machine. The clamping fixture used must be strong enough to hold the aluminum securely in place during machining without damaging the surface of the material. This can be achieved using a combination of clamps and vacuum suction.

After the material is in place, the CNC machine is programmed to perform the cutting operation. CNC machines are equipped with different numbers of axes depending on their complexity and purpose, most aluminum machining processes require 2 or 3 axis CNC machines.

Two-axis CNC machines are used for simple straight cuts, while three-axis machines can produce more complex shapes using rotary cutting tools. During the cutting process, the aluminum sheet rotates and moves along the machine's X and Y axes, a cutting tool controlled by a computer program removes the excess material.

After the machining process is complete, the aluminum sheet is removed from the CNC machine and the finished product is checked for precision and quality. The finished aluminum panels are then shipped to the next stage of the production process, which may be powder coating, anodizing or simply painting.

If you are looking for a reliable company for providing you with high quality CNC machining parts, please feel free to contact us. We provide the highest quality manufacturing services to ensure our customers get the best products.

Products Description:

Product Material | 1) AL1060, AL6061, AL6061, AL5052 2) Steel, mild steel, SPCC 3) SS201, SS303, SS304, SS316, SS316L 4) SPTE, galvanized sheet 5) Brass, copper 6) ABS, PP, PE, PC, POM |

Surface Treatment | Anodized, powder coating, lacquer coating, black oxide, printing, Nikel Plating, antioxidant, etc |

Size | 1) According to customers' drawings 2) According to customers' samples |

Drawing Format | Step, dwg, igs, pdf |

Certifications | GB/T 19001-2016, ISO9001:2015 |

Payment Term | T/T, L/C, Trade Assurance |

Sample Features:

|  |

| |

|  |

Production Process:

Production Facilities:

|  |

|  |

|  |

FAQ:

Q: How soon can I get the sample after order released?

A: Usually, low quantity samples can be shipped out within 10 working days, For large volume demand, lead time need to Recalculate.

Q: Can I have customization without drawing?

A: Yes, you can send us the sample, we will scan it and make 2/3D drawing.

Q: Do you have MOQ request?

A: No MOQ limit, please send your demand to us for quotation.

Q: What’s the shipping methods you use?

A: 1. For low quantity, we prefer to use TNT, DHL, EMC, Fedex, UPS, Or other express you required.

2. For large quantity, shipping by sea or Air.

With our strong economic strength and adherence to the principle of honesty, we have gained the trust of our customers and a good reputation in the carbon steel SA36 SS41 CNC drilling Machining heat exchanger Tube Sheets Baffles Support Plates Tube Plates Tubesheets industry. We vigorously promote the spirit of craftsmanship and professionalism, and constantly improve our professional ability and level. Our company insists on winning by quality and improving competitiveness.

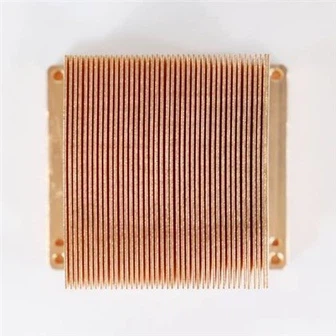

Hot Tags: CNC machining plate, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China, CPU Cooler, Copper Vapour Chamber Heatsink, Stainless Steel Plate, Micro Stamping Sink, Thermal BackPlate, Copper CPU Heatsink

You Might Also Like

-

Custom Carbon Steel Metal Stamping Part with Powder Coated

-

Heat Exchanger (HCZA-260-000-100)

-

Factory Custom Extruded /Bond/Skived Aluminum Fin Heatsink

-

Custom High Power Forged Black Pin Fin Heatsink with Adapted Cut-out for Wiring

-

White Powder Coolant Ws-12 Cooling Agent Food Additive for Vape Ejuice and Eliquid

-

CPU Cooler for Intel Socket LGA 115X/1200, K69237-001

Send Inquiry