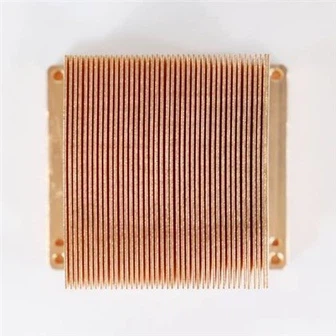

Black Anodized Aluminum Skived Fin Heatsink

Skiving technology uses the skiving machine to peel the fins from a solid aluminum or copper bar with designed space, fin thickness and height, this process allows high fin density and ratio aspect. So it can create more surface area to dissipate the heat, aluminum heat sinks usually need to do surface finish, black anodizing is the most common type. A skived fin heat sink offers maximum thermal performance in a given space, compared with other manufacturing process, skiving technique offers thinner fins, denser fin pitch and high aspect ratio which provides more heat dissipation area, and due to the skived fins are sliced from the base, so the thermal resistance between the fin and base is very low, which makes the heat sink has great thermal conductivity. The thermal conductivity of copper is ~400W/m-k, which is best conductor of heat in all the commercial metals, so a copper skived fin heat sink can remove the heat from the CPU rapidly and dissipate to the air quickly. it is a great thermal solution for CPUs and other electronic components.

Product Introduction

Skiving technology uses the skiving machine to peel the fins from a solid aluminum or copper bar with designed space, fin thickness and height, this process allows high fin density and ratio aspect. So it can create more surface area to dissipate the heat, aluminum heat sinks usually need to do surface finish, black anodizing is the most common type.

A skived fin heat sink offers maximum thermal performance in a given space, compared with other manufacturing process, skiving technique offers thinner fins, denser fin pitch and high aspect ratio which provides more heat dissipation area, and due to the skived fins are sliced from the base, so the thermal resistance between the fin and base is very low, which makes the heat sink has great thermal conductivity. The thermal conductivity of copper is ~400W/m-k, which is best conductor of heat in all the commercial metals, so a copper skived fin heat sink can remove the heat from the CPU rapidly and dissipate to the air quickly. it is a great thermal solution for CPUs and other electronic components.

The benefits of black anodized aluminum skived fin heat sink:

1, Aluminum heat sink has excellent thermal conductive, lightweight, cost efficient character;

2, Aluminum skived fin heat sink has more fins in a limit space than extrusions which means it has better thermal performance;

3, No joint between the fins and base allows for the rapid thermal conductivity;

4, Black anodizing can protect the heat sink from corrosion, wearing, and electric conduction.

Product specifications

| Material | Aluminum and copper | Certificates | ISO 9001:2015,ISO 14001:2015 |

| Product dimension | Customized | Type | Skived fin heat sink |

| Process | Skiving, CNC | Lead time | 2-3 weeks |

| Surface finish | Passivation, anodizing | Packing | Tray, carton |

| OEM/ODM | Yes | Quality control | 100% |

| Application | CPU, inverter,IGBT,LED,etc. | Warrantly | 1 year |

Varieties of heat sink

Thermal simulation

Factory and workshop

Certificates

As a leading skiving fin heat sink manufacturer, Sinda Thermal possesses several high precision skiving fin machines and can manufacture the high quality and cost effective skived fin heat sinks, we own several patents on skiving fin heat sink manufacturing which can produce higher precise and production yied skiving heat sinks. except black anodizied aluminum skived fin heat sink, we also supply copper skived fin heat sink, and other process type heat sinks like cold forging heat sink, aluminum extruded heat sink, soldering heat sink assemly, die casting heat sink, etc. Sinda Thermal is a professional and experienced heat sink supplier, please contact us if you have any thermal issues or heat sink demand.

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: black anodized aluminum skived fin heatsink, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China, Skived Fin Process, Skived Fin Copper Heat Sink, Aluminium Skiving Fin Heatsink, Skived Fin Heatsink

You Might Also Like

Send Inquiry