Aluminum Extruded Inverter Heat Sinks

In the modern digital age, the demand for power electronics is continuously growing, devices such as mobile phones, computers, and electric cars have become our daily companions. However, as this demand continues to grow, the thermal management is also a big challenge for the power electronics, an efficient thermal solution is very important. Heat sinks play an essential role in the control of the temperature of the device, and aluminum extruded heat sink is the main type of thermal solutions.

Product Introduction

In the modern digital age, the demand for power electronics is continuously growing, devices such as mobile phones, computers, and electric cars have become our daily companions. However, as this demand continues to grow, the thermal management is also a big challenge for the power electronics, an efficient thermal solution is very important. Heat sinks play an essential role in the control of the temperature of the device, and aluminum extruded heat sink is the main type of thermal solutions.

An inverter is an electronic device that converts direct current (DC) into alternating current (AC). The conversion process leads to the production of a lot of heat, which must be efficiently dissipated to ensure the device works correctly. The design of an inverter heat sink is to transfer heat from the inverter to the environment, where it can be dissipated through natural or forced convection, the inverter has to work on a secure temperature range to keep it working normally.

Aluminum extruded heat sinks are manufactured from aluminum extrusions, a process that pushing aluminum billets through a die to produce long aluminum profiles. Multiple extrusions are then connected to optimize cooling performance. This manufacturing process makes aluminum extruded heat sinks incredibly efficient and versatile.

So why are aluminum extruded heat sinks the main type of inverter thermal solution? there are several beneftis as below:

1. Excellent thermal conductivity

Aluminum has an incredibly high thermal conductivity of about 235 W/m.K. this high thermal conductivity means that aluminum heat sinks can transfer heat faster, and provide a more efficient cooling performance for the inverter.

2. High surface area

The extrusion process allows for the creation of complex shapes and high surface-area-to-volume ratios, this high surface area enables the inverter heat sink to dissipate heat more effectively, to improve the cooling performance.

3. Corrosion resistant

Aluminum extruded heat sinks have shown excellent resistance to corrosion, so they are more reliable and durable. The protection against corrosion results from a passive layer formed when exposed to oxygen in the atmosphere. Furthermore, aluminum extruded heat sinks are also ideal for outdoor applications since it offers excellent protection against UV rays.

4. Cost-effective

Aluminum extruded heatsink is the one of the most cost-efficient thermal solutions, aluminum is a relatively cheap metal, and extrusion process a very low cost manufacturing process, which makes the aluminum heatsink extrusion is a very cost-effective thermal option.

5. Low thermal resistance

The low thermal resistance of aluminum extruded heat sinks ensures minimal heat loss during the heat transfer process. Heat loss can sometimes occur in the form of radiation, conduction, or convection, this property means that aluminum extruded heat sinks ensure efficient heat dissipation with minimal energy consumption.

6. Lightweight

Aluminum extruded heat sinks are lightweight compared to other heat sink materials such as copper, this characteristic makes aluminum extruded heat sinks the ideal choice for portable inverter applications.

Varieties of heat sink

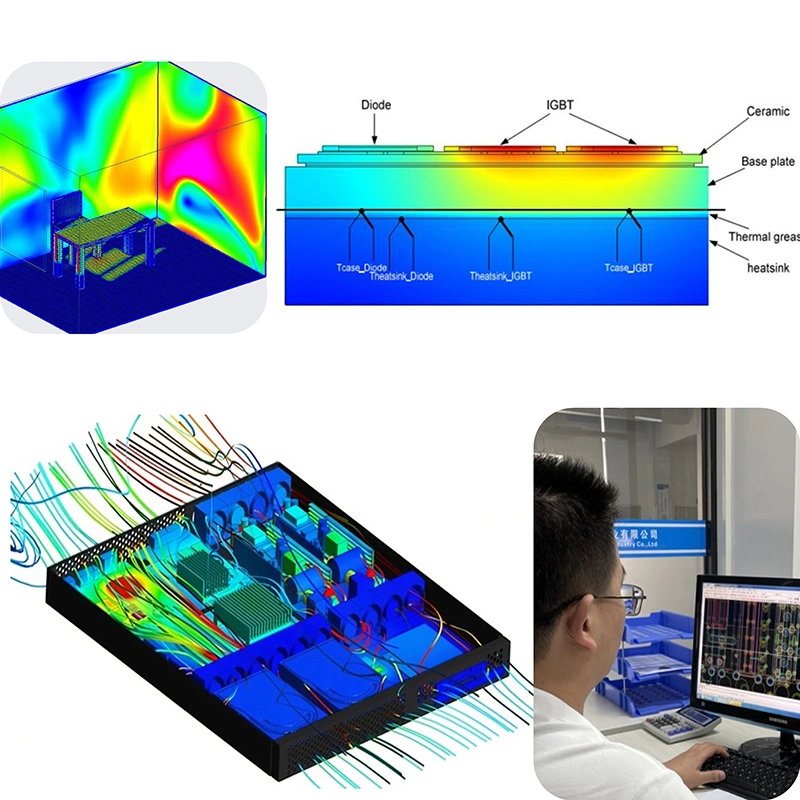

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: aluminum extruded inverter heat sinks, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China

You Might Also Like

Send Inquiry