Copper Pin Fin IGBT Heat Sink

As the insulated gate bipolar transistors (IGBTs) are widely used in power electronic devices, the need for efficient heat sinks to improve their thermal performance has become critical. One of the most effective ways to improve IGBT cooling is to use copper pin fin heat sinks. Copper is a highly thermally conductive metal that transfers heat quickly from the device to the heat sink for faster heat dissipation.

Product Introduction

As the insulated gate bipolar transistors (IGBTs) are widely used in power electronic devices, the need for efficient heat sinks to improve their thermal performance has become critical. One of the most effective ways to improve IGBT cooling is to use copper pin fin heat sinks. Copper is a highly thermally conductive metal that transfers heat quickly from the device to the heat sink for faster heat dissipation.

IGBT is a power semiconductor that combines the characteristics of MOSFET transistors and bipolar transistors, due to their dual performance characteristics, IGBTs have become important components in many applications and systems, such as renewable energy, electric vehicles, and high-voltage motor drives. However, the high power density and high operating temperature of IGBTs can lead to severe thermal problems that shorten their lifetime and affect their performance.

To solve these problems, copper pin fin heat sinks have become one of the most efficient thermal management solutions in the IGBT industry, the copper pin fins are designed to increase the surface area of the heat sink, allowing more heat to dissipate into the surrounding air, also copper material can reduce the thermal resistance of the heat sink due to its excellent thermal conductivity.

The thermal performance of copper pin fin heat sinks for IGBTs is highly dependent on various factors such as copper fin thickness, fin density, airflow and heat sink geometry, the thickness of the copper fin determines its mechanical strength and the thermal resistance provided by the heat sink. Thicker fins, while providing better mechanical support, also increase thermal resistance and reduce the rate of heat dissipation. The fin density indicates the number of fins per unit length, which determines the heat transfer area for heat dissipation. The high number of fins per unit length provides a larger heat transfer area for better thermal performance. In addition, the geometry of the heat sink is also an important factor in determining the heat dissipation performance.

In addition, airflow strongly affects the performance of copper pin fin heat sinks, so the heat sink design should allow optimal air flow over the heat sink surface to maximize heat transfer, This can be achieved by using forced air cooling or natural convection, depending on the application.

Varieties of heat sink

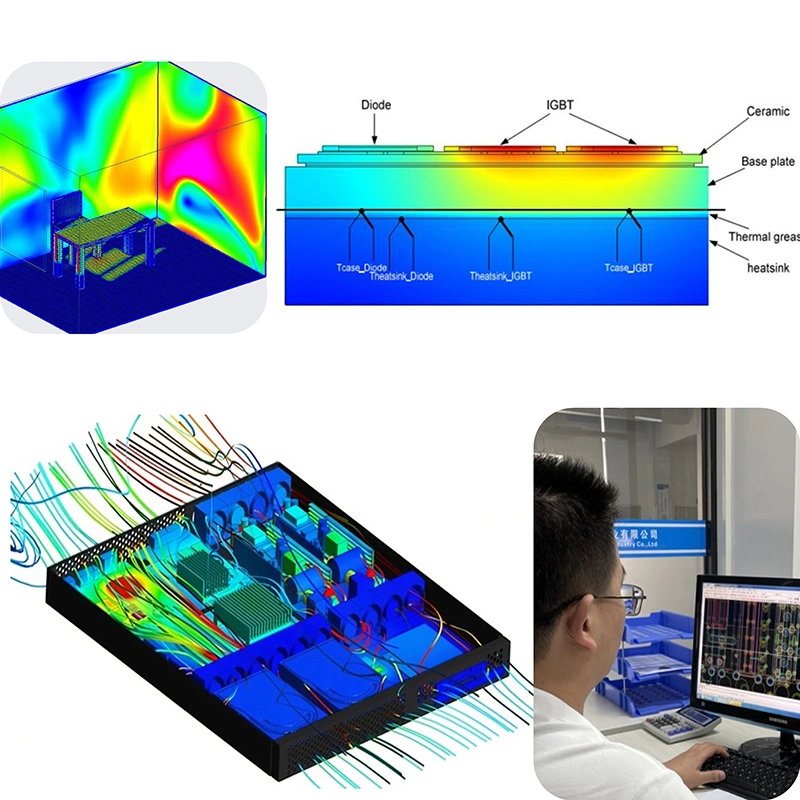

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: copper pin fin igbt heat sink, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China

You Might Also Like

Send Inquiry