Water Cooled Heat Sink For IGBT

IGBTs convert electrical energy into heat when they are switched. This heat must be dissipated away from the IGBT in order to maintain proper device operation and prevent damage. Without proper heat dissipation management, the IGBT could experience thermal runaway and fail during operation. Heat sinks are an effective way to manage the heat generated by IGBTs. They work by increasing the surface area available for heat dissipation, allowing heat to be transferred away from the IGBT and into the ambient environment more efficiently. This helps to prevent the IGBT from overheating and failing, ensuring reliable device operation.

Product Introduction

IGBTs, or insulated gate bipolar transistors, are key components in a wide range of power electronics applications, from motor drives to renewable energy systems. They offer high switching speeds and high voltage ratings, making them an attractive choice for power conversion applications that require efficient and reliable operation. However, one challenge associated with using IGBTs is managing their heat dissipation, to solve the thermal issues, heat sinks are often used to help reduce the temperature of the IGBT during operation. Water cooled heat sinks can be one of the most effective solutions for managing high heat loads.

Why do IGBTs need heat sinks?

IGBTs convert electrical energy into heat when they are switched, this heat must be dissipated away from the IGBT in order to maintain proper device operation and prevent damage, without proper thermal management, the IGBT could experience overheating and fail during operation. Heat sinks are an effective way to manage the heat generated by IGBTs, the heat sinks dissipate heat by the excellent thermal conductivity and large surface area, allowing heat to be transferred away from the IGBT and into the ambient environment more efficiently, this helps to prevent the IGBT from overheating and failing, ensuring reliable device operation.

What is an IGBT heat sink?

An IGBT heat sink is a device that is designed to transfer heat away from the IGBT during operation, it is typically made of a thermally conductive material, like aluminum or copper, and has fins or other features to increase the surface area available for heat dissipation, the heat sink is attached to the IGBT using a thermal interface material, like thermal grease or pads, this interface material helps to improve the thermal contact between the IGBT and the heat sink, ensuring efficient heat transfer.

When is a water cooled heat sink needed for IGBTs?

While air cooled heat sinks are commonly used to manage the heat generated by IGBTs, they may not always be sufficient to handle high heat loads. In some applications, water cooled heat sinks may be needed to ensure proper heat dissipation. Water cooled heat sinks offer several advantages over air cooled heat sinks, including higher heat dissipation capabilities and more precise temperature control. They are typically used in applications where the heat load is high and a higher level of temperature control is required. Examples of applications where water cooled heat sinks may be needed include:

- High power motor drives

- Large scale solar inverters

- Power supplies for industrial applications

- Electric vehicle battery chargers

In these applications, the IGBTs may generate a significant amount of heat, requiring a more sophisticated cooling solution. A water cooled heat sink can provide the necessary cooling performance, ensuring reliable and efficient device operation.

Benefits of using water cooled heat sinks for IGBTs

Water cooled heat sinks offer several benefits over air cooled heat sinks in certain applications. Some of these benefits include:

- Higher heat dissipation capabilities: Water has a higher heat transfer coefficient than air, meaning it can transfer more heat away from the IGBT for a given flow rate. This allows water cooled heat sinks to handle higher heat loads more efficiently than air cooled heat sinks.

- Precise temperature control: Water can be circulated through the heat sink at a specific flow rate to maintain a precise temperature. This allows for more accurate temperature control of the IGBT, which can be critical in some applications.

- Silent operation: Water cooled heat sinks do not require high speed fans like air cooled heat sinks do, resulting in silent operation.

- Smaller form factor: Water has a higher heat transfer capability than air, meaning a water cooled heat sink can be smaller in size for a given heat load than an air cooled heat sink.

Varieties of heat sink

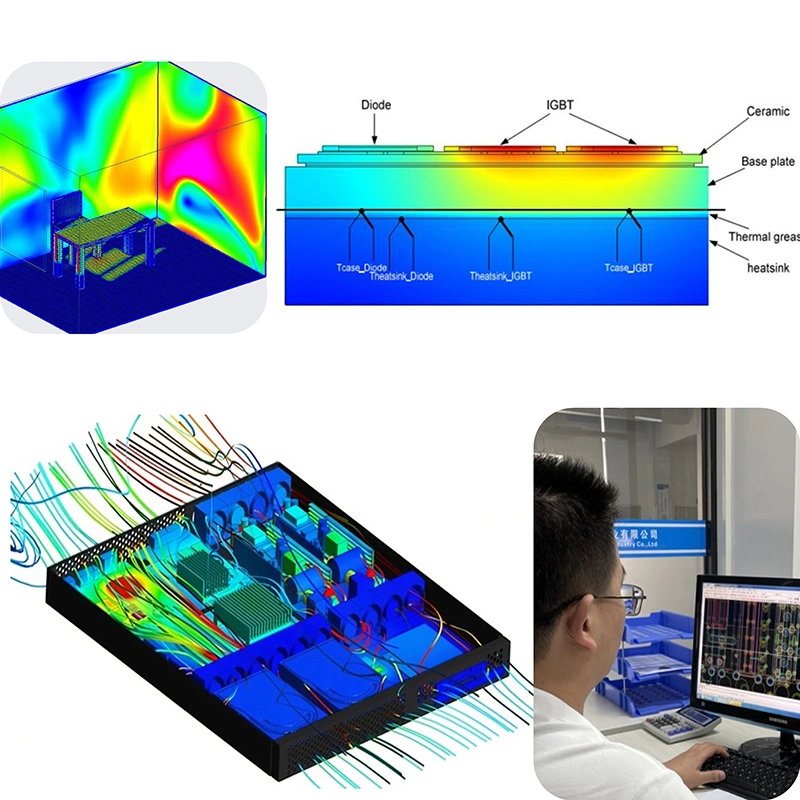

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: water cooled heat sink for igbt, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China

You Might Also Like

Send Inquiry