Vapor Chamber Heat Sinks

In recent years, vapor chamber heatsinks have gained popularity due to their efficient heat dissipation capabilities. These advanced cooling solutions are increasingly popular in the electronics industry and offer many advantages over traditional heat sink designs.

Product Introduction

In recent years, vapor chamber heatsinks have gained popularity due to their efficient heat dissipation capabilities. These advanced cooling solutions are increasingly popular in the electronics industry and offer many advantages over traditional heat sink designs.

Vapor chamber heat sinks are essentially an evolution of traditional heat sinks, utilizing the principle of phase change cooling to provide superior thermal performance. The key to its effectiveness lies in its structure, which consists of a sealed chamber filled with a small amount of liquid coolant. As the components on the heatsink generate heat, the liquid within the vapor chamber evaporates and moves throughout the room, carrying heat away from the heat source. When the vapor reaches cooler areas of the chamber, it condenses back into liquid and the cycle continues, effectively moving heat away from the component and dissipating it into the surrounding environment.

One of the main advantages of vapor chamber heatsinks is their ability to spread heat more evenly across the surface of the heat sink. This allows for a more even temperature distribution, prevents hot spots and reduces the risk of thermal throttling, which can negatively impact the performance and service life of electronic components. In addition, vapor chamber heat sinks can handle higher thermal loads compared to traditional heat sinks, making them suitable for high-performance applications such as gaming PCs, servers, and industrial equipment.

Another major advantage of vapor chamber radiators is their compact design. Unlike traditional heat sinks, which often consist of numerous heat pipes and fins, vapor chamber heat sinks can achieve the same level of thermal performance in a smaller, lighter form factor. This is particularly beneficial in space-constrained electronic devices, allowing for better thermal management without compromising size or weight.

Additionally, vapor chamber radiators have higher thermal conductivity than traditional heatsinks. Using liquid coolant allows for more efficient heat transfer, resulting in lower thermal resistance and improved overall cooling performance. This reduces the operating temperature of electronic components, significantly extending their service life and reliability.

In addition to thermal benefits, vapor chamber radiators also offer better acoustic performance. By efficiently dissipating heat, they reduce the need for higher fan speeds, resulting in quieter operation. This is especially important for applications where noise levels are a concern, such as audio equipment or home entertainment systems.

The introduction of vapor chamber radiators represents a significant advancement in thermal management technology. These innovative cooling solutions offer superior heat dissipation, improved thermal conductivity, compact design and quieter operation, making them an attractive option for a variety of electronic devices. As the demand for high-performance and reliable electronics continues to grow, vapor chamber heat sinks are expected to play a vital role in meeting these requirements and ensuring the long-term performance and reliability of electronic systems.

Varieties of heat sink

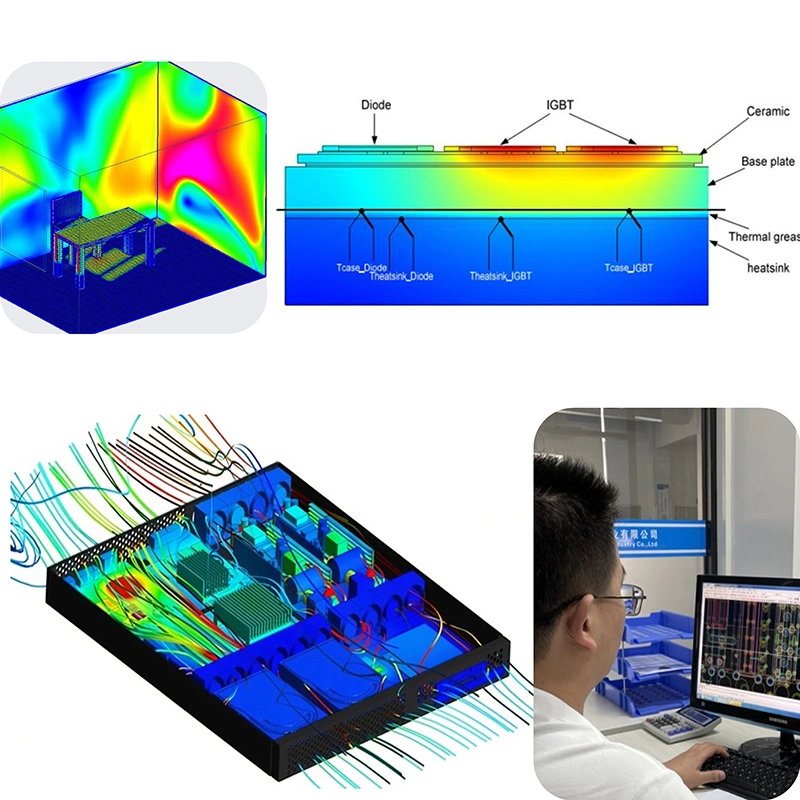

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: vapor chamber heat sinks, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China

You Might Also Like

Send Inquiry