Vapor Chamber Heatsinks

A vapor chamber heatsink is a cooling solution that consists of a flat plate with a sealed cavity inside that is filled with a small volume liquid coolant. The coolant is usually water, which is heated by the electronic components. The heat causes it to evaporate, and as the vapor absorb the heat and rises to contact with the cooler surfaces of the vapor chamber. The vapor then condenses back into a liquid, releasing heat in the process. The liquid then flows back into the chamber by the capillary force from the wick structure inside the chamber, where it is heated again, and the cycle repeats. This continuous process results in efficient heat spreading and transferring, keeping the electronic components cool and preventing it from overheating.

Product Introduction

A vapor chamber heatsink is a cooling solution that consists of a flat plate with a sealed cavity inside that is filled with a small volume liquid coolant. The coolant is usually water, which is heated by the electronic components. The heat causes it to evaporate, and as the vapor absorb the heat and rises to contact with the cooler surfaces of the vapor chamber. The vapor then condenses back into a liquid, releasing heat in the process. The liquid then flows back into the chamber by the capillary force from the wick structure inside the chamber, where it is heated again, and the cycle repeats. This continuous process results in efficient heat spreading and transferring, keeping the electronic components cool and preventing it from overheating.

Like heat pipe, Vapor chamber is also a two phase thermal device, inside the sealed chamber, we usually put some copper pillars to reinforce the stiffness of the vapor chamber plate, and sinter some copper mesh or powder to build a wick structure which create a capillary force to drive the condensed liquid back to the heat source area. As the thermal medium is coolant, so we inject a small volume water into the chamber to evaporate and condense to absorb and transfer the heat from the electronic devices. The difference between the vapor chamber and heat pipe is that the vapor in the vapor chamber can spread to many direction, which means it can spread the heat much more efficient, which makes the vapor chamber heatsink to be a high performance thermal solution.

The main advantages of using a vapor chamber heatsink is that it can solve the high power thermal issues with limited space. As the vapor chamber can absorb and spread the heat from the electornic devices rapidly, then we solder it with the aluminum zipper fins to build a high performance thermal module, when the heat was transferred to the aluminum zipper fins, the heat can be dissipated very quickly due to the extremely heat dissipation ability of the aluminum zipper fins, this combination takes full advantage of the two components, makes the vapor chamber to be a compact and high performance cooling solution. It can perfectly solve the thermal issues of some electronics system which has high power electronic components but limited space.

Varieties of heat sink

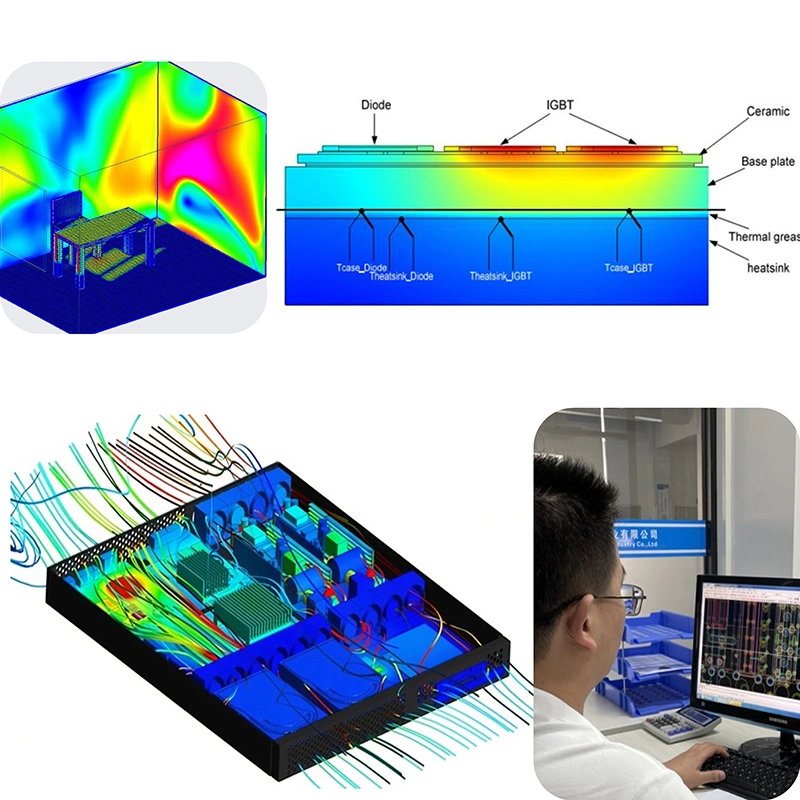

Thermal simulation

Factory and workshop

Certificates

Sinda Thermal is a leading thermal manufacturer in China, our factory was founded in 2014, and located in Dongguan city, China, we are offering varieties of heatsinks and other precious metal parts. Our plant possesses 30 sets advanced and high precious CNC machines and stamping machines, also we have many testing and experiment instruments and professional engineering team, so our company can manufacture and provide high quality products with high precision and excellent thermal performance. Sinda Thermal is commited to a range of heat sinks which are widely used in new power supply, New energy vehicles, Telecommunications, Servers, IGBT, and Madical. All the products accord with Rohs/Reach standard, and the factory is qualified by ISO9001 and ISO14001. Our company has been a partner with many customers for good quality, excellent service and competitive price. Sinda Thermal is a great heat sink manufacturer for the global customers .

FAQ

1. Q: Are you a trading company or manufacturer?

A: We are a leading heat sink manufacturer, our factory has been founded over 8 years, we are professional and experienced.

2. Q: Can you provide OEM/ODM service?

A: Yes, OEM/ODM are available.

3. Q: Do you have MOQ limit?

A: No, we don't set up MOQ, prototype samples are available.

4. Q: What's the lead time of the production?

A: For prototype samples, the lead time is 1-2 weeks, for mass production, the lead time is 4-6 weeks.

5. Q: Can I visit your factory?

A: Yes, Welcome to Sinda Thermal.

Hot Tags: vapor chamber heatsinks, China, manufacturers, customized, wholesale, buy, bulk, quotation, low price, in stock, free sample, made in China

You Might Also Like

Send Inquiry